The History of the Transit Mixer in Australia

This month we begin the story of the Concrete Transit Mixer in Australia from its earliest origins to the developments within the industry we see today.

Issue 1—Origins to WWII

The start of the Second World War heralded the origin of the Australian pre-mixed concrete industry. From its origin in 1939, the development of the Transit Mixer in Australia has evolved from a primitive, revolving drum agitator to a scientifically-designed concrete mixing machine of unequalled efficiency, delivering well in excess of over 12,000,000m3 of concrete per annum in Australia.

Out of America – The majority of the original technology of pre-mixed concrete in Australia had originated in the USA. The industry began in the States in the early 1920’s mainly with the building of great concrete dams in the west of the continental USA. The central mixing plants used in the construction of these dams were usually equipped with large horizontal drum or tilting mixers which produced a homogeneous mix.

However, the transportation of the mixed concrete in tip carts and dump bodies undid much of the thorough mixing, due to the segregation which occurred in the non-agitating road vehicles. American know-how came up with initial solutions, which included the use of steam-powered mixers at the site, to which dry batch materials were delivered.

The inflexibility of this system soon became obvious and tethered with the development of the motor lorry, it wasn’t long before suitable horizontal mixers and agitators were fitted to the lorries for the transportation of the mixed concrete.

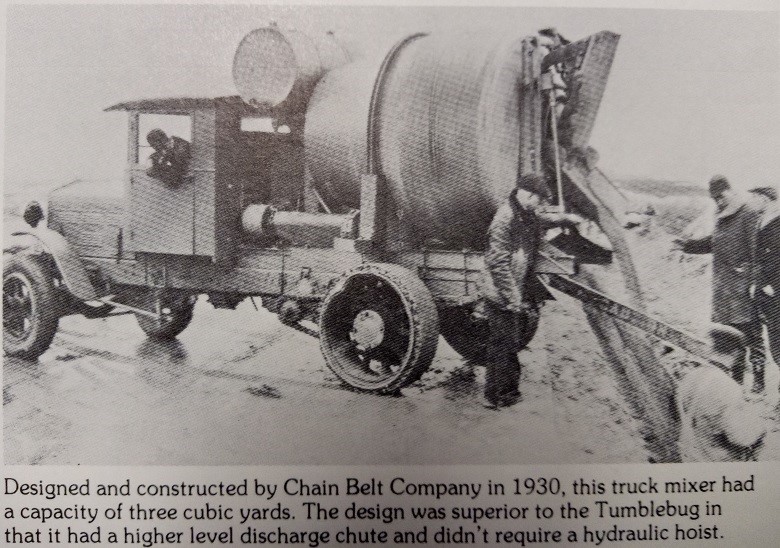

One of the pioneers of concrete mixing ma-chines in the USA was the Chain Belt Co. of Mil-waukee, which became famous in the early part of the century for its “Rex” Stationery Mixers. The Rex drum mixer was amongst the first to be modified to fit Vintage trucks and what eventu-ally became known as the “Transit Mixer”.

The Australian Immigration to the War Years

The first Australian pre-mixed plant using a fleet of agitators at Glebe Island, Sydney was also of American design and its construction was supervised by an American, the late Ray Wood of Seattle – the co-founder of Fowler Wood Engineering. The Glebe plant was operated by the newly-formed Ready Mixed Concrete limited.

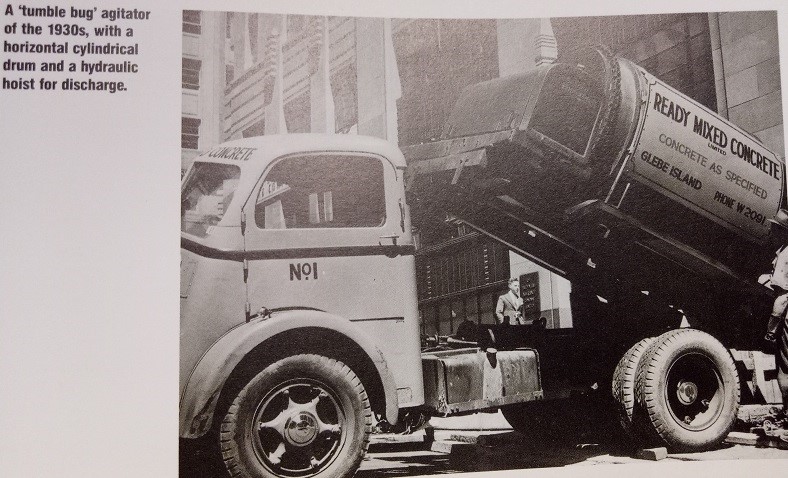

The plant incorporated a “Rex”3 cubic yard stationary central mixer and it had a fleet of horizontal drum agitators known as “Tumblebugs” mounted on 1939 model White Trucks. These machines could not mix but they could agitate and prevent segregation in transit and were a vast improvement on the tip truck or dump buggy hauling of pre-mixed concrete. The Tumblebugs were based on early American agitator design and were powered by 1925 Dodge engines and transmissions.

The drum was a horizontal cylinder with two roller tracks, mounted onto four flanged rollers. A “quick” release hatch was fitted in the side of the drum through which the mixed concrete was charged. To discharge, the drum was stopped with the rear-end guillotine door at the lowest point. The drum and frame were then elevated by hydraulic hoist, allowing the concrete to slide out under the force of gravity.

However in practice, some of the concrete would always remain in the drum. To overcome this problem, each machine was equipped with a long handled larry to enable the operator to scrape out the inside of the drum and when that failed, a sledge hammer was used to belt the drum until it was completely empty!

The guillotine door was a bit of a death trap – it weighed ½ ton and sometimes dropped down UNEXPECTEDLY! This little flaw could see an operator missing fingers if not constantly vigilant.

When empty, the machines weighed about 4 tons and they could carry about 3 cubic yards of concrete, rear axle permitting! A tad off from the present-day 8 & 10 Wheelers; even up to the giants of the industry – the 11m3 Trailer Mixers – but what a grand start.

The first fleet of Tumblebugs worked through most of the war years and were kept busy delivering pre-mixed concrete. The next major development took place in October 1944, when Certified Concrete commenced a pre-mixed concrete operation at An-nadale, Sydney.

The new company built eighteen 2 ½ cubic yard inclined axis transit mixers – the design based on a Smith machine. These units were mounted on International KBS.5 trucks, the only trucks remotely suitable during the war years. On site water would be add-ed for mixing at the point of delivery. The largest pour made by this fleet was 223 ¾ cubic yards at Waddington’s, Granville on a Saturday morning. The mixers were powered by a Dodge engine and Model T Ford gearbox. Here ended this industry segment which takes us up to the end of WWII.

*Pictures and Excerpts edited & sourced from: 1/ The Australian Truck Mixer – Its Origin and Development, published by NRMCA (National Ready Mixed Concrete Association of Australasia). 2/ 200 Years of Concrete in Australia by Miles Lewis, published by the Concrete Institute of Australia.